Understanding the Applications of PTFE Lined Pipe and Fittings

When it comes to handling corrosive chemicals and fluids in industrial settings, PTFE (Polytetrafluoroethylene) lined pipes and fittings play a crucial role in ensuring the safety and efficiency of the operations. As a leading supplier of PTFE piping systems, Jiangsu Yihao Fluorine Plastic Manufacturing Co., Ltd. offers a comprehensive range of PTFE pipes, sheets, rods, gasket sheets, and various types of rings. In this article, we will delve into the differences between PFA and PTFE lined pipes and the specific applications of Diflon PTFE lined pipes and fittings.

Diflon PTFE lined pipes and fittings are designed to provide a reliable and long-lasting solution for conveying corrosive fluids in chemical processing plants, pharmaceutical industries, and other industrial applications. The non-adhesive and consistent quality of PTFE lined steel pipes make them an ideal choice for handling a wide range of aggressive chemicals. The low permeability and considerable wall thickness of PTFE lined pipes ensure minimal absorption of the conveyed fluids, thereby maintaining the purity and integrity of the substances being transported.

PTFE Ring and Packing

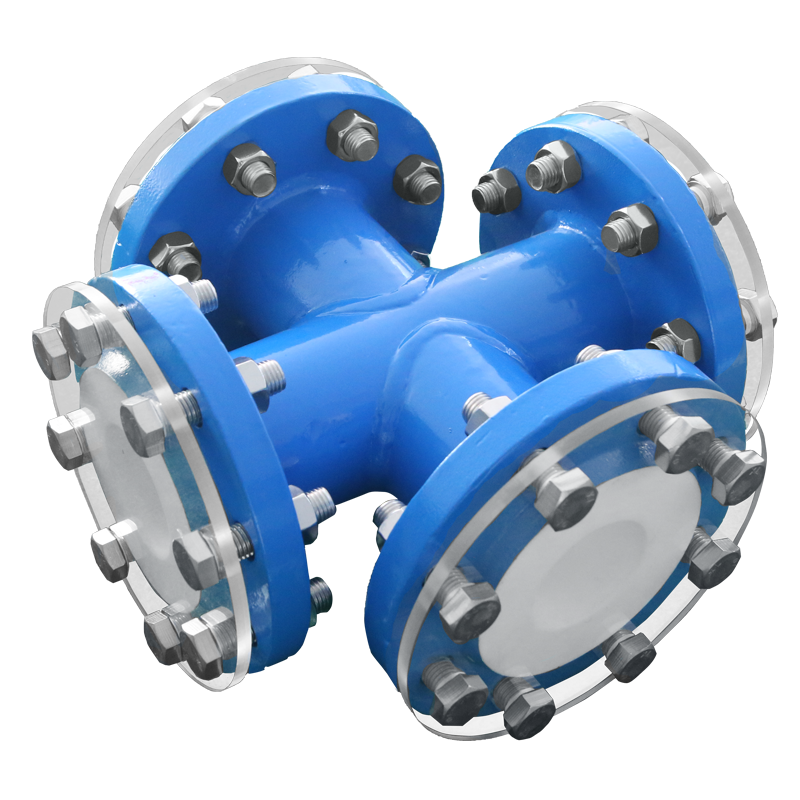

PTFE Ring and Packing PTFE Lining Steel Pipes and Fittings

PTFE Lining Steel Pipes and Fittings PTFE Lined Vessels and Packing

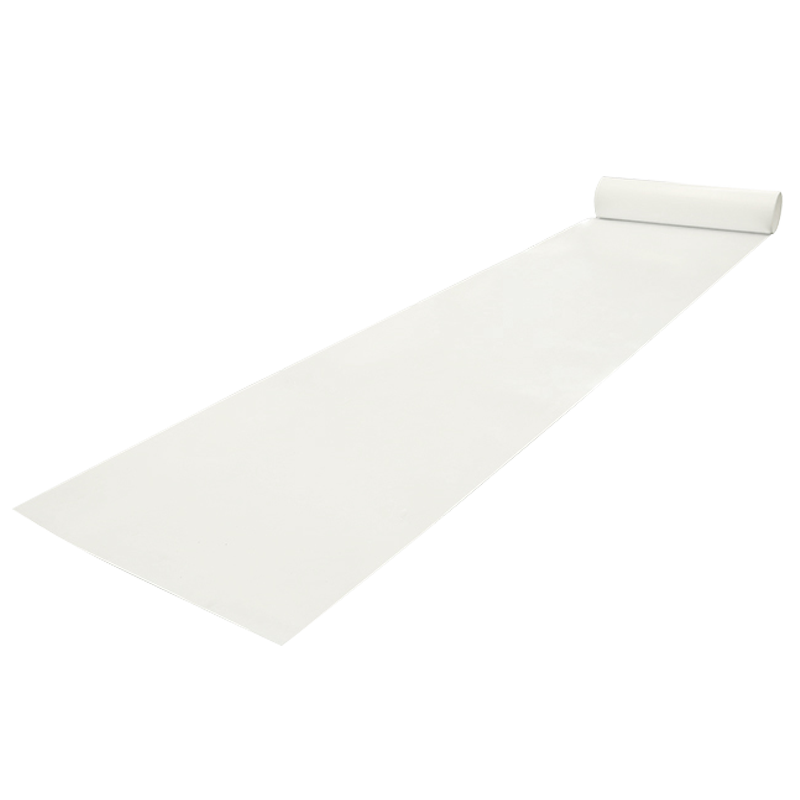

PTFE Lined Vessels and Packing PTFE Sheet

PTFE Sheet PTFE Pipe

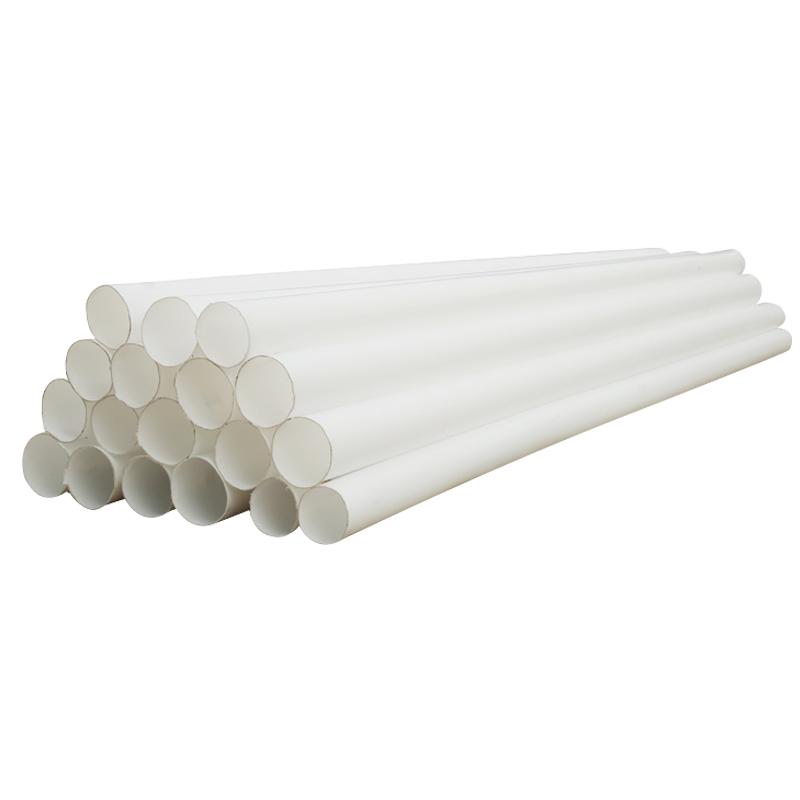

PTFE Pipe PTFE Lined Steel Pipe/Tube

PTFE Lined Steel Pipe/Tube