0102030405

Sebaka sa hajoale se tsebahalang sa machaba sa PTFE sa lisebelisoa tsa tlhahiso ea liphaephe - kettle e nang le phaephe ea isostatic pressure kettle

2024-06-18 00:24:10

Khamphani ea rona - Jiangsu Fuhao Yihao Plastic Industry Co., Ltd., e fumaneha Yancheng, Jiangsu. Khamphani ea rona e na le lisebelisoa tse felletseng tsa tlhahiso le tlhahiso bakeng sa liindasteri tse amanang, 'me ketlele e kholo ka ho fetisisa ea isobaric naheng ea China e fekthering ea rona.

Thepa ena e kenyelletsa sebaka se tsebahalang hajoale sa machaba sa PTFE se nang le liphaephe tsa tlhahiso ea liphaephe - kettle e nang le lipeipi tsa isostatic pressure kettle. Isostatic pressing ke mokhoa oa ho eketsa porcelain ea granulated ho hlobo, eo hangata e entsoeng ka polasetiki kapa rabara e nang le tekanyo e itseng ea elasticity. Mochineng oa khatiso oa isostatic, khatello e ts'oanang ea li-megapascal tse mashome ho ea ho tse makholo e sebelisoa ho hlobo ho kopanya le ho etsa porcelain e nang le granulated ka har'a hlobo. Ho na le mekhoa e 'meli ea ho hatella isostatic: ho tobetsa ha isostatic ho batang le ho hatella ho chesang ha isostatic. Cold isostatic pressing e arotsoe hape ka mekhoa e metsi le e omileng. Mokhoa o batang oa ho hatella isostatic o sebelisoang Chaena hangata o kolobile. Joalo ka khatello e omileng, granulation e boetse e etsoa pele o hatelloa ka isostatic. Phapang ke hore ho sebelisoa likaroloana tsa phofo tsa granulation feela bakeng sa khatiso e chesang ea isostatic.

0102030405060708

Molao-motheo o sebetsang oa ho hatella isostatic ke molao oa Pascal: "Khatello ea seaplane (metsi kapa khase) ka setsing se koetsoeng e ka fetisoa ka ho lekana ka mahlakoreng 'ohle." Theknoloji ea khatiso ea Isostatic e na le nalane ea lilemo tse fetang 70 mme qalong e ne e sebelisoa haholo ho metallurgy ea phofo bakeng sa ho etsa phofo; Lilemong tse 20 tse fetileng, theknoloji ea "isostatic" e 'nile ea sebelisoa haholo ho lahla ceramic, matla a athomo, tlhahiso ea lisebelisoa, polasetiki, graphite, ceramics, magnets e sa feleng, libotlolo tsa porcelain tse phahameng tsa khatello ea motlakase, ho lokisetsa biopharmaceutical, lijo. ho boloka, lisebelisoa tse sebetsang hantle, indasteri ea sesole, lisebelisoa tsa bongaka, meriana le masimo a mang.

1.Cold isostatic tobetsa

Cold Isostatic Pressing (CIP) ke theknoloji eo ka tloaelo e sebelisang rabara kapa polasetiki e le thepa ea ho paka hlobo ka mocheso oa kamore, e nang le mokelikeli e le mochini oa khatello, o sebelisetsoang haholo ho etsa phofo, ho fana ka billet bakeng sa sintering e eketsehileng, calcination, kapa ho chesa. mekhoa ea ho hatella isostatic. Khatello e akaretsang ea tšebeliso ke 100-630MPa.

2.Mofuthu oa khatello ea isostatic

Theknoloji e futhumetseng ea ho hatella isostatic hangata e sebetsa ka mocheso o hatellang oa 80-120 ℃. Ho boetse ho na le lino tse khethehileng kapa likhase tse sebelisoang ho fetisa khatello ka mocheso oa 250-450 ℃, ka khatello e sebetsang e ka bang 300MPa. Haholo-holo e sebelisoang bakeng sa lisebelisoa tsa rabara tsa graphite, polyamide, joalo-joalo tse ke keng tsa etsoa ke lisebelisoa tsa phofo mocheso oa kamore. Ho fihlella billet e tiileng ka mocheso o phahameng.

3.Hot isostatic tobetsa

Hot isostatic pressing (HIP) ke theknoloji ea ts'ebetso e lumellang lisebelisoa hore li kene tlas'a khatello ea isostatic tlas'a ketso e le 'ngoe ea mocheso o phahameng le khatello e phahameng. Ha e sebelisoe feela bakeng sa ho tiisa phofo, empa hape le bakeng sa ho kopanya li-workpieces, ho felisa bofokoli ba ho lahla, le ho hlahisa likarolo tse rarahaneng tse bōpehileng ka mekhoa ea setso ea metallurgy. Ka khatello e chesang ea isostatic, likhase tsa inert tse kang argon le ammonia hangata li sebelisoa e le mecha ea phatlalatso ea khatello, 'me thepa ea ho paka hangata ke tšepe kapa khalase. Mocheso oa ho sebetsa hangata o pakeng tsa 1000 ~ 2200 ℃, 'me khatello ea ho sebetsa hangata e pakeng tsa 100 ~ 200MPa.

Melemo ea Isostatic Pressing Technology

E le mokhoa oa ho theha, theknoloji ea ho hatella ea isostatic e na le litšobotsi tse latelang ha li bapisoa le mekhoa e tloaelehileng ea ho etsa:

1. Boima ba lihlahisoa tse entsoeng ka ho hatelloa ha isostatic ka kakaretso ke 5 ~ 15 e phahameng ho feta ea ho bōpa unidirectional le bidirectional. Boima bo lekantsoeng ba lihlahisoa tse hatellang tsa isostatic tse chesang li ka fihla ho 99.8% ~ 99.09%.

2. Boima ba compact bo tšoana ebile bo tsitsitse. Ts'ebetsong ea ho bopa, ebang ke ho hatella ka tsela e sa lekanyetsoang kapa ka bidirectional, kabo e sa lekanang ea compact density e tla etsahala. Phetoho ena ea boima hangata e ka fihla ho feta 10% ha o tobetsa lihlahisoa tse rarahaneng. Sena se bakoa ke ho hanyetsa ha likhohlano pakeng tsa phofo le hlobo ea tšepe. Khatello e fetisitsoeng ke isostatic pressure fluid medium e lekana ka mahlakoreng 'ohle. Khatello ea sephutheloana le phofo hangata e lumellana, 'me ha ho na motsamao o lekanyelitsoeng pakeng tsa phofo le sephutheloana. Khanyetso ea likhohlano pakeng tsa bona e nyane, mme khatello e fokotseha hanyane. Sekhahla sena sa density hangata se ka tlase ho 1%. Ka hona, ho ka nkoa hore boima ba billet bo tšoana.

3. Ka lebaka la boima bo tšoanang, bolelele ba bolelele ba bophara ha bo felle, bo leng molemo bakeng sa ho hlahisa lihlahisoa tse tšesaane le tse telele ka mokhoa oa melamu le li-tubes.

4. Ts'ebetso ea ho hatella isostatic ka kakaretso ha e hloke ho eketsoa ha mafura ho phofo, e fokotsang tšilafalo ho sehlahisoa le ho nolofatsa mokhoa oa ho etsa lihlahisoa.

5. Lihlahisoa tse entsoeng ka ho hatella isostatic li na le ts'ebetso e babatsehang, potoloho e khutšoanyane ea tlhahiso, le mefuta e mengata ea kopo. Mefokolo ea ts'ebetso ea ho hatella isostatic ke ts'ebetso e tlase ea ts'ebetso le lisebelisoa tse theko e boima.

Hajoale, k'hamphani ea rona e thehile tšebelisano ea khoebo le bareki ba bangata lapeng le kantle ho naha, 'me e sebelisitse thepa ena ho hlahisa lihlahisoa tse fapaneng tsa liphaephe tsa PTFE. Lihlahisoa tse ka hare tsa liphaephe tse hlahisoang ke thepa ena li na le boleng bo botle haholo, ho hanyetsa ho hatelloa ka mokhoa o babatsehang, 'me khokahanyo ea ka hare ea lesela e kenngoa ka thata ntle le likheo, e nang le bokahare bo boreleli le bo bataletseng. Khamphani ea rona e amohela ka mofuthu bareki ba nang le litlhoko tsa ts'ebetso ea tlhahiso ho sebelisana le rona molemong oa bobeli le liphetho tsa win-win!

PTFE Ring le Packing

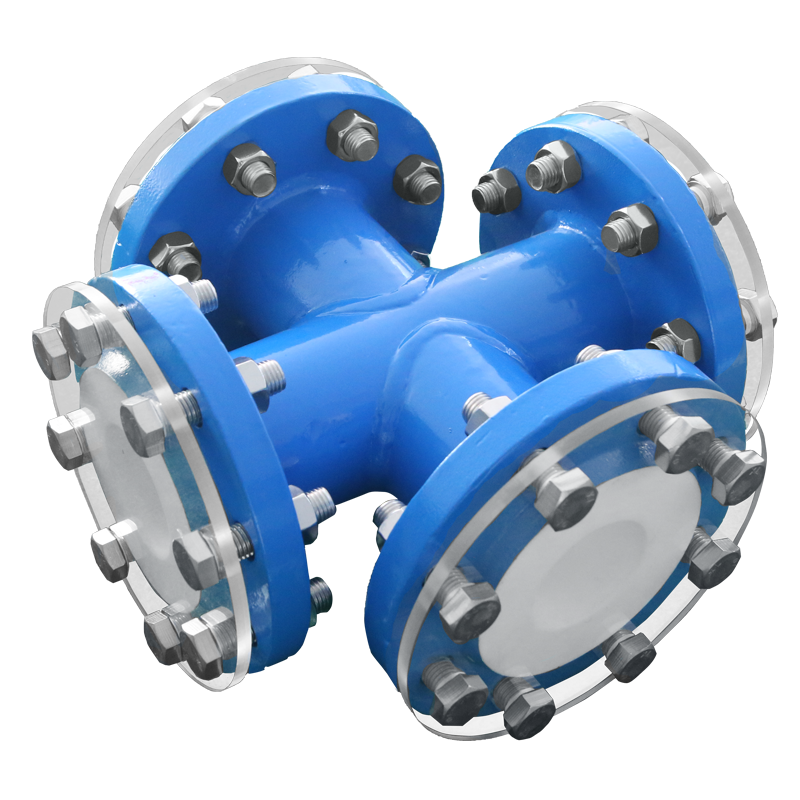

PTFE Ring le Packing PTFE Lining Liphaephe tsa tšepe le Fittings

PTFE Lining Liphaephe tsa tšepe le Fittings PTFE Lined Lijana le Packing

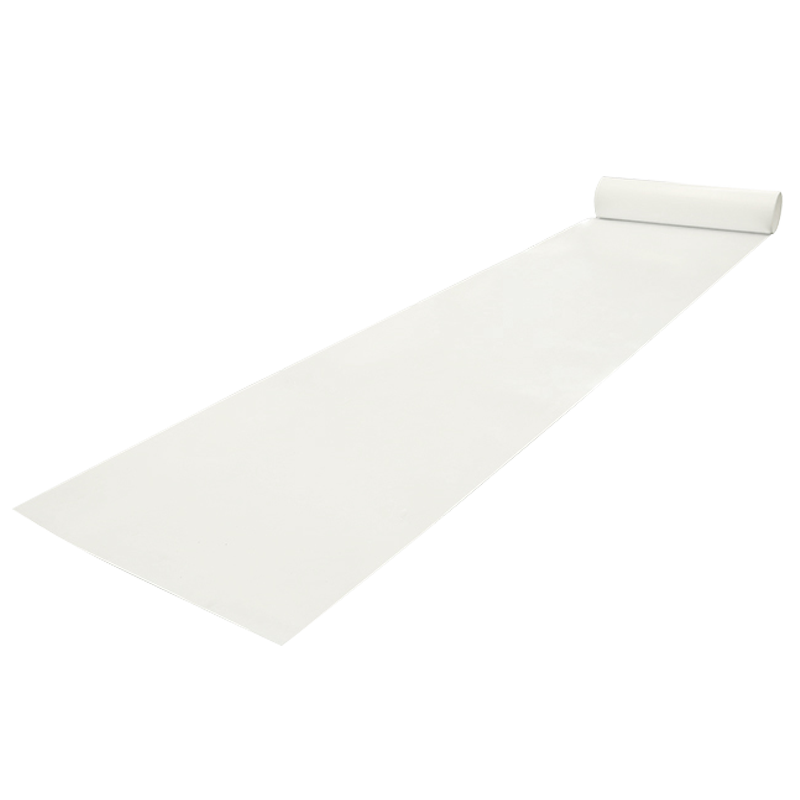

PTFE Lined Lijana le Packing Letlapa la PTFE

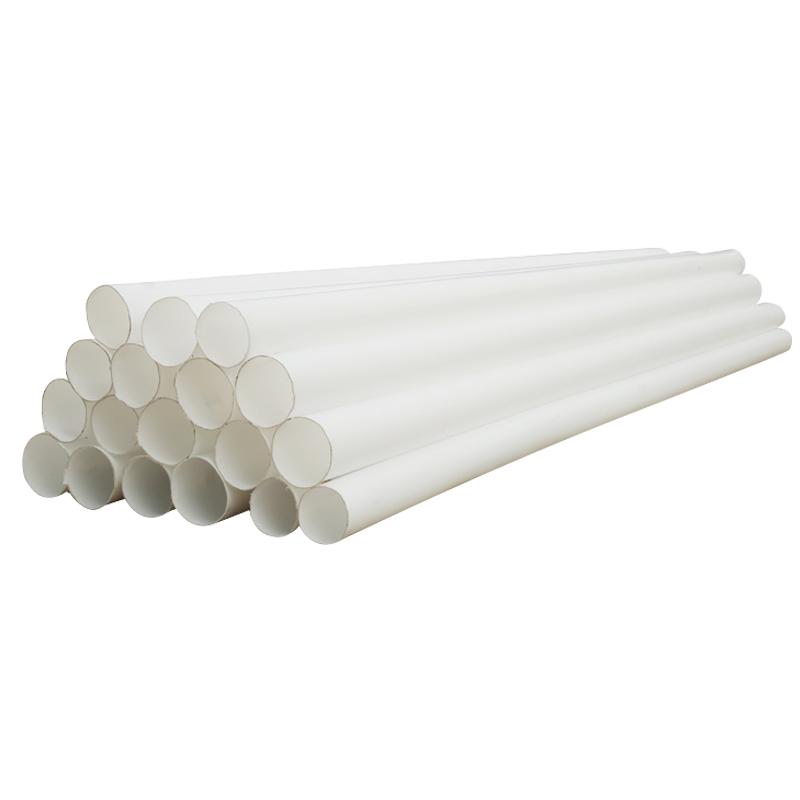

Letlapa la PTFE Pipe ea PTFE

Pipe ea PTFE PTFE Lined Steel Pipe/Tube

PTFE Lined Steel Pipe/Tube