0102 ib0304 ib05

Tam sim no nrov thoob ntiaj teb PTFE lined pipeline ntau lawm khoom teb - lined pipeline isostatic siab kettle

2024-06-18 00:24:10 dr hab

Peb lub tuam txhab - Jiangsu Fuhao Yihao Plastic Industry Co., Ltd., nyob hauv Yancheng, Jiangsu. Peb lub tuam txhab tau ua tiav kev tsim khoom thiab tsim khoom siv rau cov kev lag luam muaj feem xyuam, thiab qhov loj tshaj plaws isobaric kettle hauv Suav teb yog nyob rau hauv peb lub Hoobkas.

Cov cuab yeej no suav nrog qhov tam sim no nrov thoob ntiaj teb PTFE lined pipeline ntau lawm cov khoom siv teb - lined pipeline isostatic pressure kettle. Isostatic nias yog cov txheej txheem ntawm kev ntxiv granulated porcelain rau pwm, uas feem ntau yog ua los ntawm cov yas lossis roj hmab nrog qee qib ntawm elasticity. Nyob rau hauv ib qho isostatic pressing tshuab, ib tug uniform siab ntawm kaum mus rau pua pua ntawm megapascals yog siv rau cov pwm kom compact thiab zoo li tus granulated porcelain nyob rau hauv pwm. Muaj ob txoj hauv kev rau isostatic nias txoj kev: txias isostatic nias thiab kub isostatic nias. Txias isostatic nias ntxiv muab faib ua cov txheej txheem ntub thiab qhuav. Txoj kev txias isostatic nias siv hauv Suav teb feem ntau yog ntub. Zoo li qhuav nias, granulation kuj yog ua ntej isostatic nias. Qhov txawv yog tias tsuas yog cov tshuaj tsuag granulation hmoov feem ntau yog siv rau kub isostatic nias.

0102 ib0304 ib050607 ib08

Lub hauv paus ntsiab lus ua haujlwm ntawm isostatic nias yog Pascal txoj cai: "Lub siab ntawm qhov nruab nrab (kua lossis roj) hauv lub thawv kaw tuaj yeem xa mus sib npaug ntawm txhua qhov kev qhia." Isostatic pressing tshuab muaj keeb kwm ntawm ntau tshaj 70 xyoo thiab tau pib tsuas yog siv hauv hmoov metallurgy rau hmoov sib sau; Nyob rau hauv 20 xyoo dhau los, isostatic pressing tshuab tau dav siv nyob rau hauv ceramic casting, atomic zog, cuab yeej tsim, yas, ultra-siab siab zaub mov sterilization, graphite, ceramics, hlau nplaum ruaj khov, high-pressure electromagnetic porcelain fwj, biopharmaceutical npaj, zaub mov preservation, cov ntaub ntawv ua tau zoo, kev lag luam tub rog, khoom siv kho mob, tshuaj thiab lwm yam kev lag luam.

1.Cold isostatic nias

Txias Isostatic Pressing (CIP) yog ib lub tshuab uas feem ntau siv roj hmab lossis yas ua cov khoom ntim pwm ntawm chav tsev kub, nrog cov kua ua lub siab nruab nrab, feem ntau yog siv rau cov khoom siv hmoov sib sau, muab ib daim ntawv rau sintering, calcination, lossis kub. isostatic nias txheej txheem. Kev siv dav dav yog 100-630MPa.

2.Sov isostatic siab

Qhov sov isostatic nias tshuab feem ntau ua haujlwm ntawm qhov kub ntawm 80-120 ℃. Kuj tseem muaj cov kua dej tshwj xeeb lossis roj siv los hloov siab ntawm qhov kub ntawm 250-450 ℃, nrog kev ua haujlwm siab ntawm ib ncig ntawm 300MPa. Feem ntau yog siv rau graphite, polyamide roj hmab cov ntaub ntawv, thiab lwm yam uas tsis tuaj yeem tsim los ntawm cov ntaub ntawv hmoov ntawm chav tsev kub. Yuav kom ua tiav ib qho khoom billet ntawm qhov kub siab.

3. Kub isostatic nias

Kub isostatic nias (HIP) yog cov txheej txheem thev naus laus zis uas tso cai rau cov ntaub ntawv mus rau isostatic nias nyob rau hauv ib txhij ua haujlwm ntawm qhov kub thiab txias. Nws tsis yog tsuas yog siv rau cov hmoov solidification, tab sis kuj rau diffusion bonding ntawm workpieces, tshem tawm cov tsis xws luag casting, thiab zus tau tej cov complex zoo li tus qhov chaw nyob rau hauv tsoos hmoov metallurgy txheej txheem. Nyob rau hauv kub isostatic nias, inert gases xws li argon thiab ammonia yog feem ntau yog siv raws li lub siab hloov xov xwm, thiab cov khoom ntim feem ntau yog hlau los yog iav. Kev ua haujlwm kub yog feem ntau ntawm 1000 ~ 2200 ℃, thiab kev ua haujlwm siab yog feem ntau ntawm 100 ~ 200MPa.

Qhov zoo ntawm Isostatic Pressing Technology

Raws li cov txheej txheem tsim, isostatic pressing tshuab muaj cov yam ntxwv hauv qab no piv rau cov txheej txheem sib sau ua ke:

1. Qhov ntom ntawm cov khoom tsim los ntawm isostatic nias yog feem ntau 5 ~ 15 siab dua li ntawm unidirectional thiab bidirectional molding. Cov txheeb ze ntom ntom ntawm kub isostatic nias khoom tuaj yeem ncav cuag 99.8% ~ 99.09%.

2. Qhov ceev ntawm lub compact yog uniform thiab zoo ib yam. Nyob rau hauv cov txheej txheem molding, txawm nws yog unidirectional los yog bidirectional nias, tsis sib npaug ntawm cov compact ntom yuav tshwm sim. Qhov kev hloov ceev no feem ntau tuaj yeem ncav cuag ntau dua 10% thaum nias cov khoom sib xws. Qhov no yog tshwm sim los ntawm kev sib txhuam ntawm cov hmoov thiab cov pwm hlau. Lub siab kis los ntawm isostatic siab kua nruab nrab yog sib npaug ntawm txhua qhov kev qhia. Lub compression ntawm pob thiab hmoov yog feem ntau zoo ib yam, thiab tsis muaj kev sib txheeb ze ntawm cov hmoov thiab pob. Kev sib txhuam tsis sib haum ntawm lawv yog tsawg, thiab lub siab tsuas yog txo qis me ntsis. Qhov ntom ntom gradient feem ntau tsuas yog qis dua 1%. Yog li ntawd, nws tuaj yeem txiav txim siab tias qhov ntom ntawm lub billet yog uniform.

3. Vim qhov tsis txaus ntseeg, qhov ntev rau cov diam diamio tsis txwv, uas tau txais txiaj ntsig zoo rau kev ua cov pas nrig siv nyias thiab ntev hauv cov pas nrig thiab cov yas.

4. Cov txheej txheem isostatic nias feem ntau tsis tas yuav ntxiv cov roj nplaum rau cov hmoov, uas txo cov pa phem rau cov khoom thiab ua kom yooj yim rau kev tsim khoom.

5. Cov khoom tsim los ntawm isostatic nias muaj kev ua tau zoo heev, lub voj voog luv luv, thiab kev siv ntau yam. Qhov tsis zoo ntawm cov txheej txheem isostatic nias yog cov txheej txheem qis thiab cov khoom siv kim.

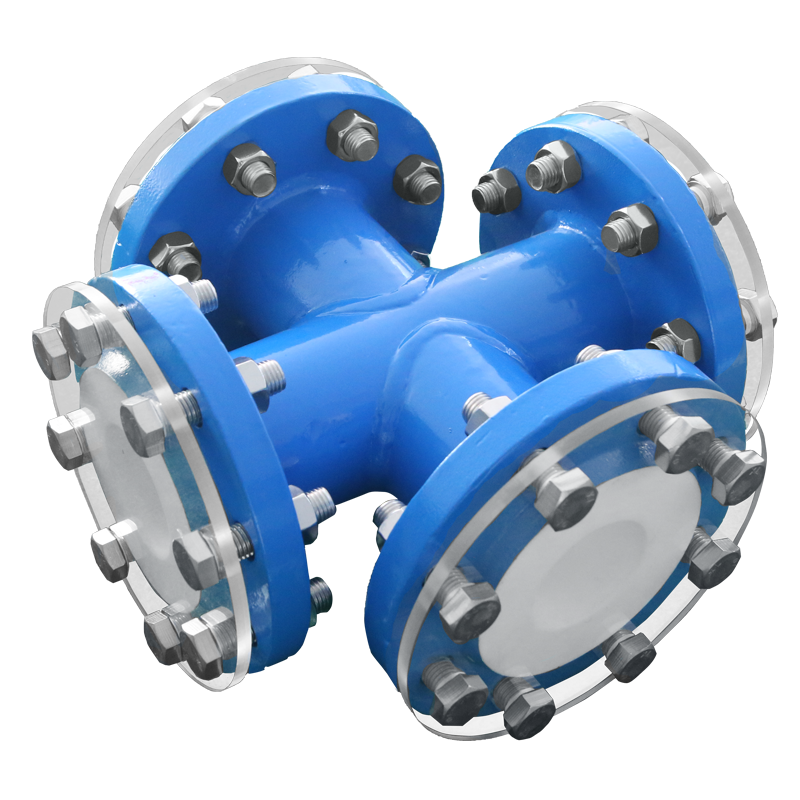

Tam sim no, peb lub tuam txhab tau tsim kev lag luam koom tes nrog ntau tus neeg siv khoom hauv tsev thiab txawv teb chaws, thiab tau siv cov cuab yeej no los tsim ntau yam PTFE lined pipeline khoom. Cov khoom siv hauv ob sab hauv cov yeeb nkab uas tsim los ntawm cov khoom siv no muaj qhov zoo heev, zoo heev compression kuj, thiab cov hauv ob sab phlu kev twb kev txuas yog nruj nreem kaw, tsis muaj qhov khoob, nrog ib tug du thiab tiaj tus sab hauv. Peb lub tuam txhab zoo siab txais tos cov neeg siv khoom nrog cov txheej txheem tsim khoom kom koom tes nrog peb rau kev sib nrig sib pab thiab yeej-yeej tau!

PTFE Ring thiab Packing

PTFE Ring thiab Packing PTFE hauv ob sab phlu steel kav thiab fittings

PTFE hauv ob sab phlu steel kav thiab fittings PTFE Lined Vessels thiab Packing

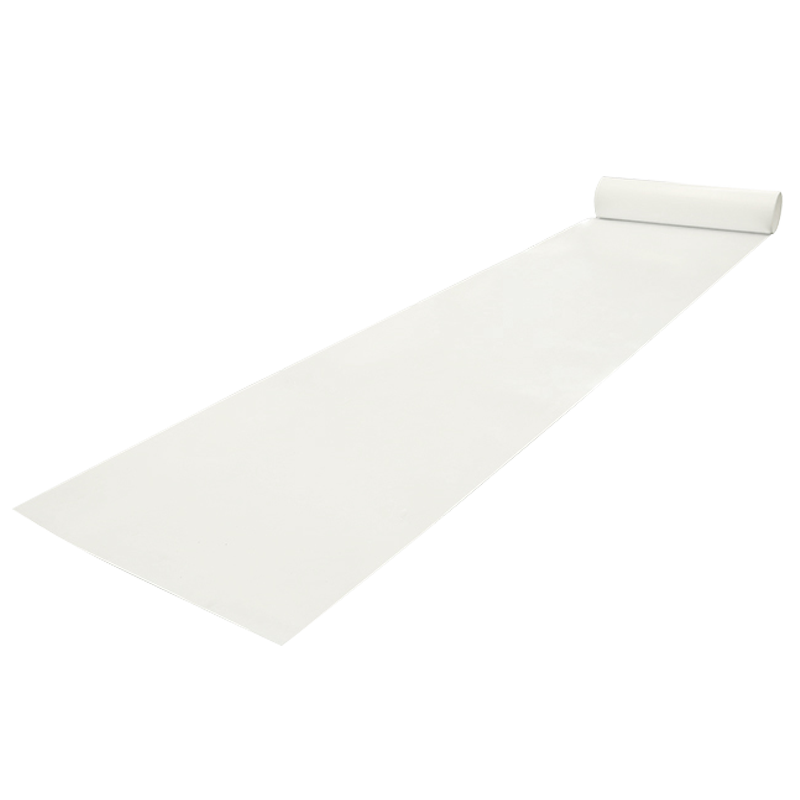

PTFE Lined Vessels thiab Packing PTFE daim ntawv

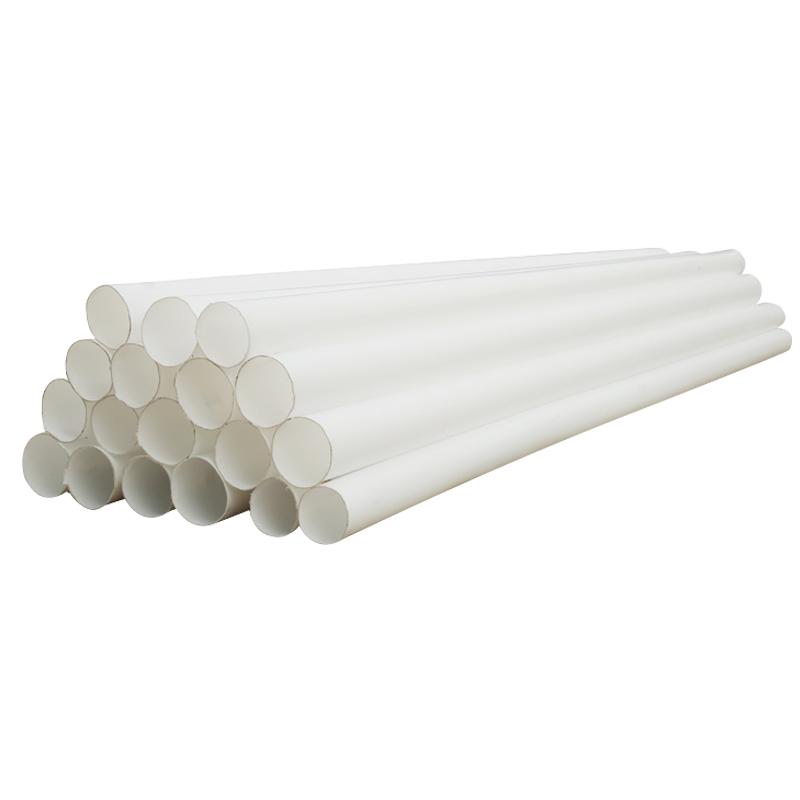

PTFE daim ntawv PTFE Tube

PTFE Tube PTFE Lined Steel Yeeb Nkab / Tube

PTFE Lined Steel Yeeb Nkab / Tube